Head Gasket Price And Quantity

- 5 Piece

Head Gasket Trade Information

- Letter of Credit (L/C) Telegraphic Transfer (T/T)

- 10000 Piece Per Month

- 30 Days

- Central America Australia South America Eastern Europe Asia

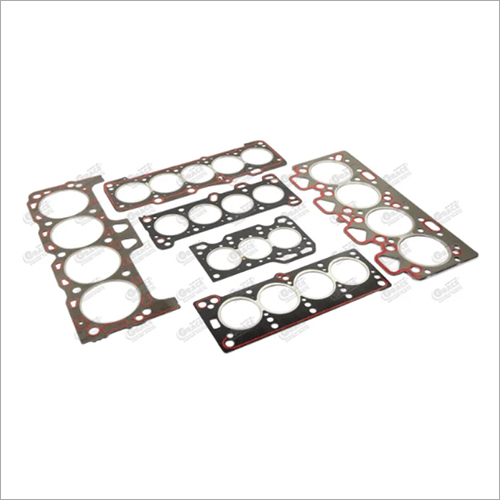

Product Description

Keeping a Cool Head

The head gasket is the primary sealing components between the engine block and the cylinder head. It not only seals but also transmits forces across the head block interface, thus influencing the overall force distribution in the engine system substantially.

This places extreme demands on the head gasket to seal the combustion chamber completely at all points of the combustion cycle. Hence head gaskets need to be designed and manufactured using very durable materials.

Garima Global supplies components for a wide variety of on road, off road, industrial and stationary applications such as: automotive light duty and light commercial, trucks heavy duty, tractors agricultural, earthmoving and construction machinery, generators, irrigation pumps, and defence special purpose vehicles.

DESIGN

Some engine designs employ single cylinder head gaskets for each individual cylinder of the engine, particularly in high horsepower engines where there might be as many as 16 24 cylinders and a single head gasket might prove too unwieldly. However, for most engines a one-piece head gasket with cylinder bores cut into it sits between the block and the head.

MATERIAL

MULTILAYER STEEL GASKETS METALOFLEX GASKETS

High performance gasoline and diesel engines demand effective sealing performance even under extreme temperatures and pressures, which is where multilayer steel gaskets display their technical excellence over any other type of head gasket. They usually consist of one or multiple layers of metal sheets with beads around areas required to be sealed and elastomer coating optional to promote micro sealing.

Half beads provide two line compression which is enough around liquid passageways, outer profile of the gasket and bolt holes while full beads generate three line compression to resist extreme ignition pressures around the combustion chamber. Various stopper designs like honeycomb, serpentine and segment stoppers are used to elastically pre-stress components like the cylinder liner around the combustion chamber, to counter dynamic fluctuations in the sealing gap while limiting unfavourable deformation of the sealing beads.

METAL ELASTOMER HEAD GASKETS

Representing the next level of head gasket technology, metal elastomer gaskets consist of a base metal sheet, mostly alloyed steel, stainless steel or spring steel, into which are embedded

Purely plastic bead materials to provide high sealing pressure at combustion chamber, and

Elastomer sealing lips in conjunction with vulcanised diaphragms at liquid circuit portals coolant and engine oil passageways to minimize sealing pressure at these locations.Thus bolt force can be optimized, as most of it will be transferred to locations where it is needed the most, i.e. at the combustion chamber. To further control the spread of bolt force in this area a special design element like a separate combustion chamber base layer may be applied around the cylinder bore of the gasket.

Metal-elastomer gaskets are used in heavy duty utility vehicles and similar rugged applications where higher sealing pressures around the combustion chamber are mandatory. AutoGRACE brand metal elastomer gaskets are manufactured by the foremost manufacturers of head gaskets in India with whom Garima Global has developed a comprehensive range suitable for light, medium and heavy duty applications.

FERROELASTIC ELASTOMER / FIBER COMPOSITE HEAD GASKETS

Striking the optimum balance between effective sealing ability and cost, these gaskets consist of a perforated metal sheet bonded to asbestos-free elastomers on both sides, with a metal border at the combustion chamber to increase sealing pressure and protect the elastomers from high temperatures. They possess good sealing capability which may be enhanced locally using additional sealing aids like washers, eyelets, grommets etc. A linear elastomer red bead may also be applied which acts like a liquid seal for further enhancing sealing at vulnerable / high-pressure locations.

However, the sealing effect is distributed over the entire gasket surface, which mandates higher head bolt forces. Low elastic resilience is a pronounced disadvantage of this type of gasket hence for engines with high thermal loads higher performance materials have been developed.

GRAPHITE COMPOSITE HEAD GASKETS

Perforated metal sheet usually steel is mechanically bonded to flexible graphite sheets on both sides, which results in a corrosion resistant, radiation resistant and versatile gasket. Any surface imperfections of the graphite layer may be addressed through elastomer coatings, usually 5 100 microns thick, chosen according to the media being sealed off, in this case combustion gases and liquids like coolants and lubricating engine oil. These coatings also help prevent sticking of the gasket to the hot surfaces.

COPPER COMPOSITE HEAD GASKETS

Combining the malleability and high thermal conductivity of copper with the strength of fibre composite layers, copper gaskets are suitable for high-performance automotive as well as industrial applications. They are able to deliver sealng performance even with rough surface finish at the head block interface but require additional machining of grooves to accommodate O rings.

No matter which type of head gasket you require, rest assured that AutoGRACE head gaskets will confirm to the highest technical standards since they are manufactured by leading manufacturers of head gaskets in India.

Other Products in 'Engine Parts' category

|

GARIMA GLOBAL PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |